Articles

See All

If This Works, The Global Mining Sector Will Change Forever–For the Better

I love this story. It appears to be true scientific sleuthing coming up with a big prize–kudos to CIO Reza Kafaei (the main inventor/chemist) and CTO Hanif Jawari and his team at RSOLV if this gets very real very quick. I’ve written this story with a bit more (bullish) drama than most reports I do because of that. But this could still take a long time to unfold. Or not.

Imagine transforming a legacy industrial process that uses one of the most toxic chemicals on Earth—cyanide—and replacing it with a clean, scalable solution. That’s the opportunity in front of RZOLV Technologies Inc. (“RZL TSXV”) today.

The global gold recovery industry is worth over $2 billion per year in cyanide-based reagents alone. Cyanide has long been the workhorse of gold extraction, but its dangers are well known: ecosystem damage, tailings failures, public backlash, and regulatory bans. Without cyanide, community support and permitting could be A LOT easier.

Now picture this: a proprietary, water-based, non-cyanide reagent that performs just as well—or better—in recovering gold from ore, waste, and tailings. AND it works on (more toxic) sulphide ores as well as oxide ores! I’ll explain below how important that is. That is revolutionary.

AND it neutralizes leftover cyanide on contact, cleaning up old minesites.

That’s what RZOLV claims to offer with its proprietary chemistry, validated by third-party labs and now moving into commercial-scale pilots.

If they’re right, this isn’t just a chemical innovation—it’s a clean-tech reimagining of how the world extracts gold.

From the Lab Bench to Global Pilots

RZOLV CEO Duane Nelson explains it clearly: “We’ve done the bench testing. We’ve run thousands of samples. Now we’re proving it works at scale.”

The results from a 100 ton sample—the largest to date—is due within weeks and is potentially a major catalyst for the stock.

There’s enough technical credibility that Canada’s government is giving them research grants:

• RZOLV received $325,000 from the federal SRED program for prior R&D—and expects $500,000+ this year to support more development.

• Through the MITACS program, students from the University of British Columbia are embedded in the RZOLV lab, funded by the government, to work on electrochemical improvements.

• The National Research Council of Canada is funding the R&D of the applications of boron-doped diamond electrochemical cells for low-cost and low-Impact regeneration of the RZOLV reagent, in partnership with Element Six, a division of De Beers.

Big Mines, Big Problems, Big Potential

RZOLV is already testing ores from major global producers—some with tailings piles of 8 million tonnes, each ton holding up to a gram of gold. Many of these operations consume 4.5 kg of cyanide per ton, at huge cost and environmental risk. In some cases, their tailings ponds contain over 500 ppm of residual cyanide, far beyond regulatory thresholds.

With RZOLV’s chemistry, Nelson says, “We routinely outperform cyanide in both leach kinetics and recoveries. And our process neutralizes any leftover cyanide in the process.”

If true across a range of ore types, that’s not an incremental improvement—it’s an unlock.

Sub-Verticals with Billion-Dollar Potential

RZOLV’s real strength is its broad applicability. The reagent is designed to work across multiple flowsheets:

1. Heap Leaching

• Mainstream use-case: low-grade, low-cost, large-scale gold recovery method.

• RZOLV’s reagent claims to plug into existing heap infrastructure with minimal changes—in other words—CHEAP!!

• Cleaner chemistry means easier permitting, faster ramp-up, and fewer community objections.

2. Tailings Reprocessing

• The ESG holy grail: turning toxic waste into gold-producing assets.

• Many tailings sites hold 0.5–1.0 g/t of gold—and are already paid for and accessible.

• Cyanide is often ineffective or outright banned for tailings—RZOLV sees these as early win zones.

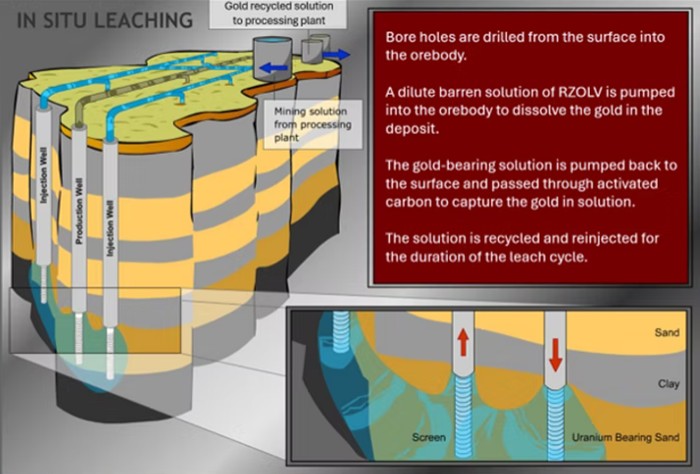

3. In-Situ Recovery (ISL)

• Disruptive potential: no mining, no tailings, just drilling and solution chemistry.

• Historically rare for gold because of groundwater concerns with cyanide.

• RZOLV’s water-based system could make ISL gold recovery not just viable—but preferred in sensitive areas.

Together, these three segments cover existing infrastructure (heap), legacy waste (tailings), and future opportunity (ISL).

4. Agitated Tank leaching

· RZOLV™ is similar cost to cyanide and recovers at least as much gold, says early results—while eliminating cyanide’s environmental and regulatory burden.

· Can be used with many kinds of ore—different grades, geology (including sulphides!!), grinding sizes etc.

5. Concentrate Treatment

· Low-cost replacement of smelters: RZOLV allows for the on-site treatment of gravity and flotation

· RZOLV delivers high recovery rates similar to smelters nut without the shipping and treatment costs.

· Eliminates payment delays, grade assay variances, and penalties for arsenic, antimony, bismuth, etc.

· The global need for smelters—one of the worst environmental factory ever made—could be almost eliminated

THE DISCOVERY PROCESS

The discovery began the way many breakthroughs do in hydrometallurgy: with frustration, failed kinetics curves, and pH logs that refused to behave.

For more than a couple years, RZOLV CTO Hanif Jafari and the team had been testing every plausible gold-complexing system known to chemical science.

Cyanide remained the global benchmark because it was simple, cheap, and ruthlessly effective—at least on oxide ores. But sulfide ores, the dark heart of the industry, were a different beast.

Sulfide-based minerology is not compliant with cyanidation due to the incompatible pH spectrums. It typically reduces gold recoveries and consumes cyanide. Many proposed non-cyanide alternatives have been tried over the last 150 years, including iodine, bromine, chlorine, thiosulfate, thiourea, acid/peroxide systems, chloride leaches, etc. All of these reagents are powerful enough to dissolve gold but are too unstable and/or too costly to survive the real world.

RSOLV CIO Reza Kafaei, left and Hanif Jawari, right

The mining industry had always assumed sulfide ores belonged to smelters.

And for a century, smelters agreed—charging harsh arsenic penalties and seizing half the economic value in the name of “processing fees.”

But chemistry has a habit of surprising the determined.

The turning point began during the RZOLV’s team’s experiments aimed at stabilizing other alternative reagents.

Traditionally, halide systems oxidize into highly reactive states, producing deep orange solutions with high ORP values—useful for dissolving gold, disastrous for everything else.

These over-oxidized states chew through steel, attack polymers, and decompose into useless chloride gas within hours. Every test so far had confirmed this instability with all the other potential alternatives tested.

But on one particular day, in a run of stabilization trials involving controlled reducing agents and complexing-ion moderators, something did not behave as expected. Instead of turning orange, the solution remained clear.

The team produced a clear, odourless and stable solution with mild operating environment and, when tested, dissolved gold at a surprising rate…

Hanif stared at the beaker, measuring the ORP again.

Stable.

Measuring the pH, low, but controlled.

Measuring free halide concentration.

Consistent.

The first test strip of gold was lowered into the solution.

Unlike halide or chloride systems that attacked gold aggressively, generating rapid oxidative spikes, this mixture pulled gold into solution in a controlled, elegant manner—steady dissolution, clean kinetics, no passivation, no runaway reactions.

A complexation mechanism was occurring—one the team couldn’t yet explain.

The second breakthrough came when the solution was reused.

Not once. Not twice.

But nine consecutive times.

Reagents that traditionally decomposed within hours showed a shelf life that defied their chemistry class. The rinse water from washed samples—diluted far beyond working strength—still dissolved measurable gold.

This was not a known halide system.

This was a chemically distinct domain.

But the real test—the one that could be oh so important to the future of gold extraction—came when they applied the new chemistry to refractory (highly complex and costly-to-process) sulfide gold and copper/gold ores.

Sulfides are notorious for their defensive strategies, meaning they chemically bind gold so tightly that only high cost processes like roasting or pressure oxidation—or smelters—can liberate it.

Here was The Big Difference:

A single reagent that dissolved gold from

1. oxides with competitive leach kinetics to cyanide,

2. and outperformed cyanide on sulfides and complex copper/gold minerologies.

And the chemistry carried more surprises…

Because the solution operated at a low pH, it destroyed cyanide on contact—converting CN⁻ into cyanate and then into CO₂ and nitrogen-bearing molecules through secondary pathways. Legacy tailings, once contaminated with cyanide residuals and metallurgical ghosts, could now be detoxified and leached simultaneously.

Then came the arsenic revelation. Yes, arsenic is highly toxic.

In sulfide concentrates, arsenic remains in solid mineral form unless intentionally mobilized. When these concentrates are treated with RZOLV in the presence of iron oxide, the arsenic can be converted into ferric arsenates—highly stable, non-leachable compounds suitable for long-term, environmentally compliant disposal. Finally, a cost-effective recovery process for gold concentrates with high arsenic values…

Suddenly, a recovery process that dissolved gold also offered a pathway to environmental cleanup.

· A recovery process that detoxified old tailings. A gold leach that bypassed smelters entirely.

· A recovery process that reduced the carbon footprint of gold production by over 90%.

· A recovery process that could be dropped directly into existing cyanide circuits—hot-swapped—without new infrastructure.

Mining engineers had long believed such chemistry could not exist. Chemical textbooks effectively agreed. But the data sheets on the lab bench told a different story: clean leach curves, stable ORP trajectories, and gold recovery efficiencies equal to or greater than cyanide.

The discovery wasn’t an accident.

It wasn’t luck.

It was the inevitable result of thousands of tests, hundreds of chemical combinations, stabilizers and oxidizers, and tens of thousands of data points—driven by a decade of refusing to accept the limits of “conventional metallurgy.”

In the end, the team realized they had not just discovered a reagent—

they had discovered a new chemical window for gold dissolution, one that neither cyanide nor halide systems had ever reached.

It appears to be a discovery that allows gold to be liberated from nearly any rock on Earth — without furnaces, without smelters, without the environmental scars of the past.

A discovery that could change the chemistry and the economics of gold itself.

Partners, Distribution, and the Global Picture

The company is in talks with:

• A European petrochemical giant about building a blending/packaging hub in Egypt, to service Africa, Asia, and Europe.

• Two of the world’s largest industrial cyanide makers and distributors, which view RZOLV not as a cyanide replacement, but as a complementary product in places cyanide can’t go. where the minerology is not compatible with cyanide, and for the onsite treatment of concentrates. Management says these combined opportunities could rival the existing $2.5B cyanide annual consumption by the sector.

• De Beers, via its Element Six unit, to co-develop diamond-based electrochemical cells for reagent regeneration.

Management says there is also in the pipeline:

• A 5-ton/day demonstration facility in Vancouver, set to be funded by a major international partner.

• Ongoing pilot programs with mining majors, who are providing feedstock and overseeing results independently.

And according to Nelson, “We’re capital-light. We’ve raised $8 million. Government grants cover 80% of our R&D. We don’t need more money right now.”

That’s rare for a pre-revenue clean-tech story.

Overcoming the Trust Barrier

As Nelson puts it: “Many have said, ‘If this works, why isn’t everyone using it?’ That’s the hurdle. It just sounds too good to be true.”

That’s why RZOLV is laser-focused on:

• Forging strong industry partnerships with chemical manufacturers and distributors

• Demonstrating predictable reproducible test results.

• Performing on-site large-scale bulk tests.

• Independent third-party results from SGS, ALS, and global labs.

• Developing strong global partnerships with engineering firms, mining equipment suppliers

• Producing positive test results for numerous mining industry giants

For those of us steeped in the mining industry, we know how conservative it is. Finding and convincing early adopters will not be easy. Though they do say they are getting 10 emails a day from the industry from all over the world…in their mind, word is getting out fast.

Wrapping the Story:

A Clean-Tech Pivot with Real Traction

So let’s step back. What’s the story here?

• Massive market: $2 billion/year in reagent spend, and a lot more in cyanide-stranded deposits.

• Toxic status quo: cyanide is under siege globally.

• Real solution: RZOLV’s chemistry is tested, scalable, and already producing lab and pilot wins.

• Public and private validation: from Canadian agencies to global miners.

• Multiple paths to scale: heap, tailings, ISL.

The next 6–12 months are crucial. If the pilots prove out, if the early partners sign on, RZOLV shifts from a clean-tech long shot to a strategic must-have in gold processing.

The next 6–12 months are crucial. If the pilots prove out, if the early partners sign on, RZOLV shifts from a clean-tech long shot to a strategic must-have in gold processing.

This isn’t about beating cyanide everywhere. It’s about being better where it matters most—where cyanide is too dangerous, too costly, or simply banned.

And that’s where RZOLV’s story may start a new chapter in how the world gets its gold.

MANAGEMENT/BOARD/ADVISORY

CEO Duane Nelson has tried something like this before–a chemical recipe story–but it didn’t quite work. So it’s possible the Street will be slow to adopt this story as an investment. But Duane knows this technology inside out. AND he has put together a very good technical team, board, and advisory board.

And it appears like this really works.

Getting all their approvals and testimonials from 3rd party labs posted on the website will help. Positive results from a 100 ton bulk sample will help. They just posted some very good

Bob Archer is on the board, and Bob is a competent respected person with a management track record. He would not lend his name lightly. Chester Millar—now 97–was at the forefront of using cyanide for oxide gold extraction via heap leach—via a company called Glamis Gold. It lowered costs dramatically. He is the honorary Chairman.

Glamis was bought out for US$8.6 billion in 2006 by Goldcorp. So there is some continuity here that he has been part of the team that takes gold extraction.

Darryl Yea was CEO of a western Canadian boutique brokerage firm, CM Oliver.

The advisory board has some market weight—Bill Shirriff is the driving force behind Encore Energy, dual listed in the US and Canada—the only US uranium producer, from ISL. Keith Peck was a successful investment banker and Bruce Bried has a strong operating background at several Canadian mines.

https://www.rzolv.com/post/turning-tailings-into-treasure-how-rzolv-s-breakthrough-technology-is-rewriting-the-future-of-gold

https://www.rzolv.com/post/breaking-the-smelter-monopoly-how-rzolv-is-making-gold-concentrate-processing-cheaper-cleaner-and